Environmental Stewardship Schemes

The University Farm has entered into Higher and Entry Level Stewardship (HLS & ELS) agreements. Options include the management under stewardship prescriptions of:

- 23.5km of hedgerows

- 7.75km of ditches

- 9.25ha of buffer strips

- 5.24ha of uncultivated field corners

- 108ha of permanent pasture managed under no or low nutrient input regimes

- 16.6ha of formerly arable land established as wildflower meadow

- 74ha of pasture managed with no nutrient input

- 6ha of extended overwintered stubble

- 7.6ha of nectar flower mixes

- 13.5ha of wild bird seed mixes.

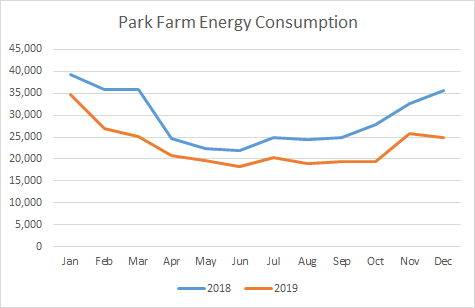

Energy Conservation

Installation of Solar Panels on Farm Buildings

- Project completed in 2011

- 12 Solar panels installed on one building

- Estimated annual savings of £2,000 on energy costs.

Robot cleaning dirty solar panels on farm building.

Lighting Replacement in Farm Buildings

- Project commissioned in February 2019.

- 34 LED luminaires replaced the existing Metal Halide luminaires in the Dairy Building, and 6 LEDs replacements made in the Straw Barn.

- The LEDs have in-built red lamps for improved staff welfare during night time working.

- £10,000 savings in annual energy consumption.

- Reduction of 22% in total carbon emissions.

Slurry & Farmyard Manure Management

Turning cow slurry into electricity

In collaboration with the Sustainability Team in Estates Division, a slurry-fuelled Anaerobic Digestion (AD) plant was installed at the Farm in the summer of 2021.

The AD plant was built to order by Belgium-based Biolectric and was delivered to the Farm in early June 2021. The assembly team, who travelled with the plant, spent three days transforming the flat pack into a fully constructed reactor. The plant began operating in July 2021 with a starter culture from a local AD plant to encourage the ‘right sort’ of microbes. The system works by collecting fresh slurry from the dairy cows which is pumped into an insulated, sealed tank. In here, the microbes (which also naturally occur in the slurry) are allowed to multiply in the warm conditions. They feed on the food material contained in the slurry producing methane as a biproduct. The methane is collected, scrubbed and pumped through to a shipping container.

Here, two engines burn this gas to generate electricity to power the Farm. Once all the food from the slurry has been consumed this digestate is pumped into one of the normal slurry towers and is applied to the grass fields to boost the grass growth. This grass is then harvested and ‘pickled’ to produce silage which is fed to the cows throughout the year. It’s important to remember that methane is produced naturally from slurry, but the controlled conditions of the reactor mean that as this is collected and burnt it reduces the CO2e (Carbon Dioxide equivalent) and produces green electricity for the Farm.

In July 2021 the plant showed steady signs of increased electricity production and in the month of August 2021, it was the second most efficient system of its size in Europe (out of approximately 315 installations!).

In 2024 the AD plant produced 229,568 KWH.

Trailing Shoe used to apply slurry